Demonstration Videos

See it to believe it - a Vaughan Chopper Pump in action speaks for itself. Follow the link below, sit back, and enjoy!

Rotamix Nozzle Assemblies

The Rotamix system uses fixed nozzle assemblies that are available in a range of single and dual nozzle configurations, depending on the tank geometry and volume of liquid to be mixed. Rotamix nozzle assemblies are designed for permanent installation inside a tank or digester. Once the assemblies are installed and nozzles aimed to factory specified angles, they are permanently tightened. No further adjustment required and there are no moving or rotating parts within the process.

Rotamix nozzle assemblies and their components are constructed from heavy-duty ductile cast materials that are then glass lined and hardened to Rockwell 70C for abrasion resistance, reduced friction, and to eliminate struvite adhesion. The tapered Rotamix nozzle barrels are a minimum 1 inch wall thickness for long-term wear protection. The entire assembly is white metal sandblasted and then powder coated with 3M™ Scotchkote™ Fusion Bonded Epoxy Coating, which is a one-part, heat-curable coating for superior surface protection. Each Rotamix nozzle assembly is covered by a 10-year full replacement warranty against wear and corrosion.

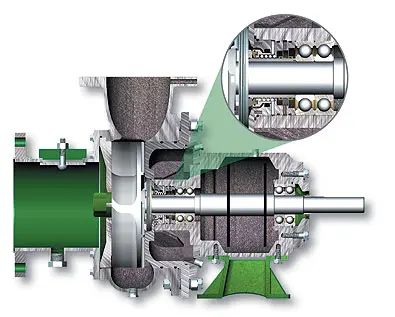

Vaughan Chopper Pump

Powering the Rotamix system is the heavy-duty Vaughan chopper pump. Vaughan’s proven technology and experience in manufacturing chopper pumps over the past 50 years ensures long-term low maintenance, and the highest reliability of any chopper pump. Continuously chopper solids not only eliminate the risk of nozzle clogging, but enhance sludge quality. Digester efficiency is increased by further reducing solids size and increasing surface contact.

Some of the key benefits offered by the Vaughan chopper pump include:

- Patented chopping action conditions solids to eliminate clogging and improve sludge quality

- Main wearing components are heat-treated to Rockwell 60C+ hardness for impact & abrasion resistance and to extend service life

- Over-sized bearing and shafting design extends pump life – B10 minimum bearing life 100,000 hours

- Heavy-duty Vaughan “flushless” cartridge seal prevents sludge dilution by eliminating the need for external flush systems (other seal configurations available)

- Back pull-out casing design with externally adjustable cutting clearances allows ease of servicing without needing to disconnect suction and discharge piping

- Available in a range of configurations, including horizontal end suction and self-priming

- Non-Clog Performance Guarantee on every pump